Diesel Forklift & Electric Forklift Comparisons

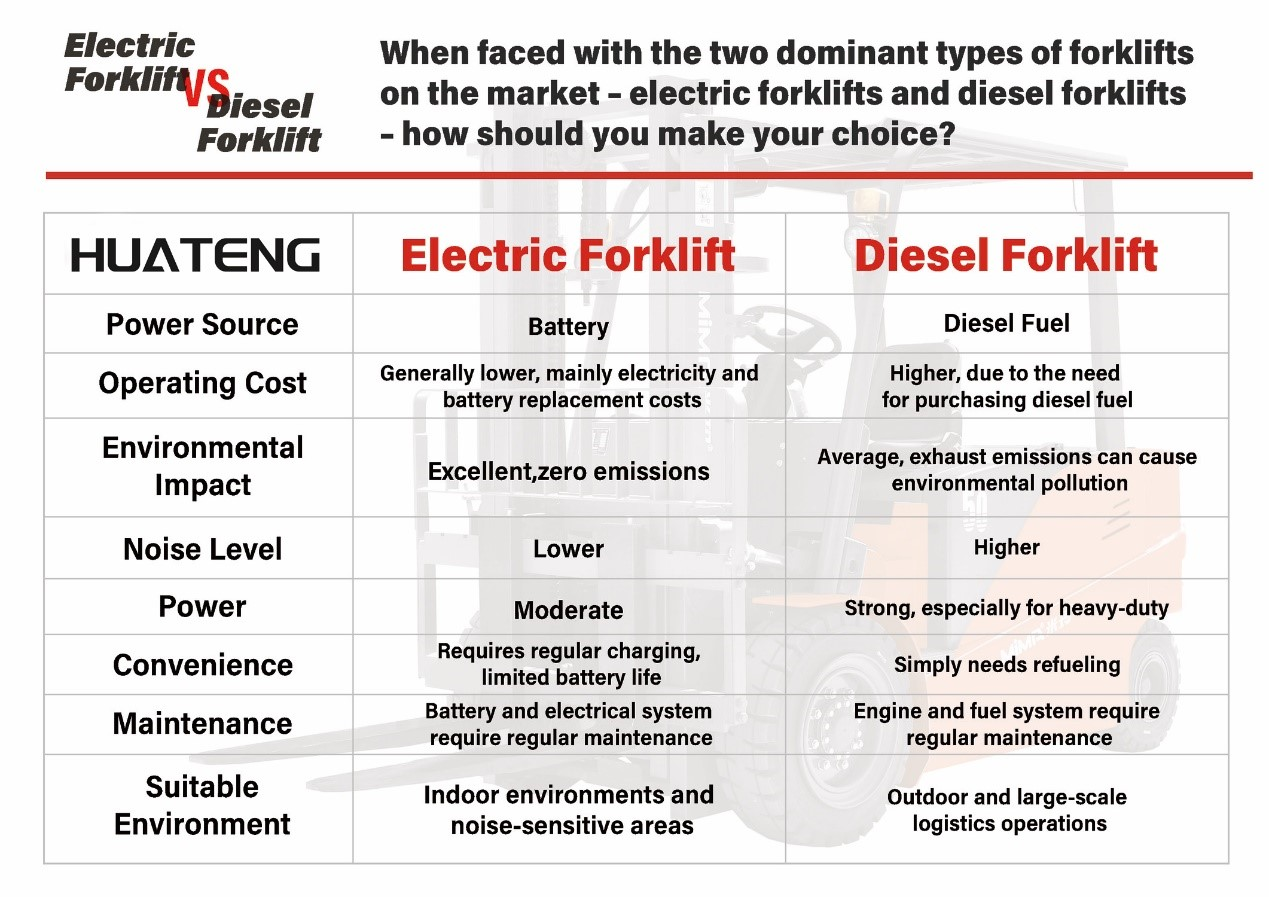

Diesel and electric forklifts do the same basic job. They both lift, load, unload and move products and materials from one place to another. They can both move large amounts of goods in a short time. This is due to their ability to safely lift and transport heavy weight loads. What separates the two is their usage.

Diesel forklifts are larger, more powerful, and are mostly used outdoors. As the name implies, they are propelled by a diesel engine. As a result, they emit harmful greenhouse fumes. Electric forklifts are more compact and have a smaller swiveling radius. This makes them better suited for warehouses and other indoor work sites. Powered by a large battery, they do not emit any exhaust fumes. This makes them friendlier to the environment and to their operators.

But there are other factors involved when comparing diesel forklifts vs electric forklifts. Let’s take a look at some of the key differences, which will help you decide if you should go with a diesel forklift or electric lift.

Diesel forklifts

Diesel forklifts are the better outdoor truck for many reasons. Their engine provides more power than electric forklifts. They are designed and built to handle rough terrain. They can withstand weather conditions better than electric models. They make more noise than electric trucks, but this is not a problem outdoors.

One real advantage of diesel trucks is they can work longer without running out of fuel. When they do run out, it only takes a few minutes to fill the fuel tank. Changing electric batteries is a longer and more complex process. It can take much longer if the replacement battery needs to be recharged before it can be put on the truck.

Diesel forklifts don’t require extra space for battery charging stations. They can also be parked anywhere instead of next to the charging station. Diesels easily outperform electrics when it comes to power usage. For example, driving on gradients will deplete an electric engine sooner than a diesel. Adding hydraulic or other attachments to the truck will also deplete an electric engine more quickly. The more components that need power from electric forklifts, the faster the battery and overall power of the forklift is depleted.

Can diesel forklifts be utilized indoors? Well, one of the drawbacks of the diesel forklifts is their extremely restricted applications in any indoor environment. Due to noise and toxic fume emissions, diesel forklifts require specialized training and certification for use at any indoor jobsite. And even if a diesel forklift is used inside, venting systems must ensure a constant flow of quality air, which many older buildings lack. Due to carbon dioxide buildup, it is hazardous to operate diesel forklifts indoors. Not impossible, but there are many hurdles to this type of forklift use.

A few cons of diesel forklift include:

Higher maintenance costs – more moving parts than electric lifts

Limited maneuverability compared to electric lifts

Restricted indoor use

More expensive to operate in the long run

Electric forklifts

Electric forklifts have been around for a while. But they didn’t start gaining in popularity until fairly recently. The rise in fuel costs and greater environmental awareness helped electric lifts gain in popularity. Today, roughly half of all new forklifts produced are electric!

With electric forklifts, workers are not forced to breathe in toxic fumes. The lower noise level makes for a safer job site. Diesel trucks can be so loud that workers often can’t hear each other when coming around corners or working in blind spots. This increases the risk of accidents that can damage goods and injure workers.

Smaller in size than diesels, electric forklifts are easier to maneuver in tight spaces such as the aisles and corners of a warehouse. They’re easier to control because the operator doesn’t have to use a clutch. Refueling electric forklifts only requires recharging or replacing the battery. There are no fuel tanks to fill. Electric trucks also have fewer moving parts that can break or get damaged. This reduces downtime and maintenance costs.

Some disadvantage of using electric lifts include:

Rarely used outdoors

Limited battery power

Higher initial costs for battery

Wait time for full charge

Pyccknй

Pyccknй

español

español

Italiano

Italiano

Français

Français

Deutsch

Deutsch